Rifle Reliability: Then and Now

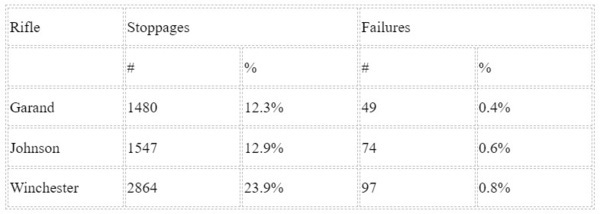

Ultimately the trials were won by the Garand, with the Melvin Johnson (Johnson Automatics) M1941 rifle placing second, and the Winchester G30M placing third in total malfunctions and broken parts. This had involved 37 different tests and more than 12,000 rounds through each rifle. The Garand had 1,480 total malfunctions and 49 parts broken, replaced, or repaired. The Johnson had 1,547 and 72 respectively, and the G30M 2,864 and 97 (roughly double the number of problems as the Garand).

Rifle Reliability Test 1940

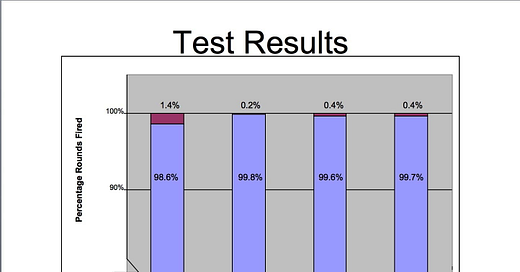

This table shows (assuming 12,000 rounds as the denominator, which is close enough because our purpose here is comparison) that as reliable as those rifles were for their day, they were pretty buggy by today’s standards. Looking at the percentages really makes the data pop.

Assuming a “malfunction” equals a stoppage, we’ll label those percentages as stoppages, and we’ll label the parts breakages as “failures.”

This was good reliability with self-loading rifles in the 1940s!

Rifle Reliability Test 2007

Compare this to the “unreliable” M4. In the worst M4 test ever, the notorious and outlying 2007 Extreme Dust Test (here and here), ten M4s fired 6,000 rounds per rifle with 1.4% stoppages.

Note, the data reported in Extreme Dust Test is over four times the number of failures reported in an earlier iteration of the same test, making the outlier EDT results (which is the only test M16/M4 haters use) something the Army Research Lab has never replicated or explained insofar as is known. This test was used in an attempt at the Congressional level to replace the M4.

Now, we can’t compare the 1940 and 2007 tests directly, however, the data indicates the M4 is nearly ten times more reliable than the M1. Even if you don’t like these numbers, any apples-to-apples comparison from any test results you like shows the M4 as significantly more reliable.

When gun prohibitionists with no shooting experience wonder why Americans keep buying firearms based on Eugene Stoner’s patent, this is one big reason why. Designs with a 98.6% success rate (and usually better than that!) make for satisfied customers.